Electrostatic Atomization

Farzad Mashayek February 23, 2015

Electrical charging of an electrically insulating liquid introduces several unique properties into the processes of primary atomization, spray dispersal, secondary atomization, lack of drop coalescence due to reduced collision probability, and significant energy efficiency savings. The EA method used by our group is based on the concept of ‘charge injection’, a technique that permits atomization and post-atomization dispersal of electrically insulating liquids with ‘off the shelf’ liquid hydrocarbon fuels, for instance Diesel oil, gasoline, Jet-A and JP-8, as well as straight vegetable oils. This is achieved by injecting electric charge directly into the liquid via a high voltage central electrode, prior to primary atomization. The liquid breakup is primarily a result of the Coulomb forces acting on the surface of the jet as it exits the orifice. The presence of these electrical forces significantly reduces the power required for atomization.

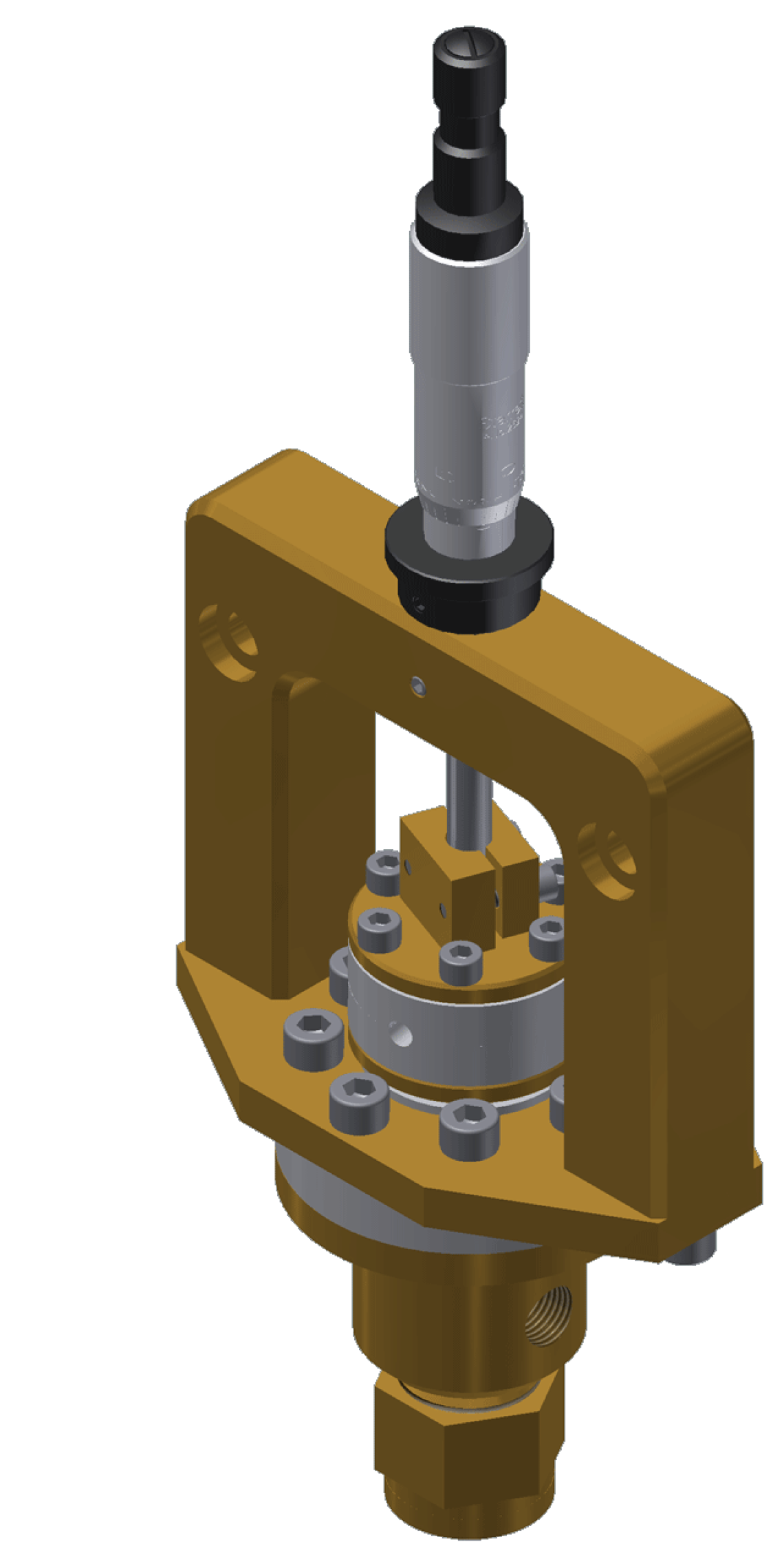

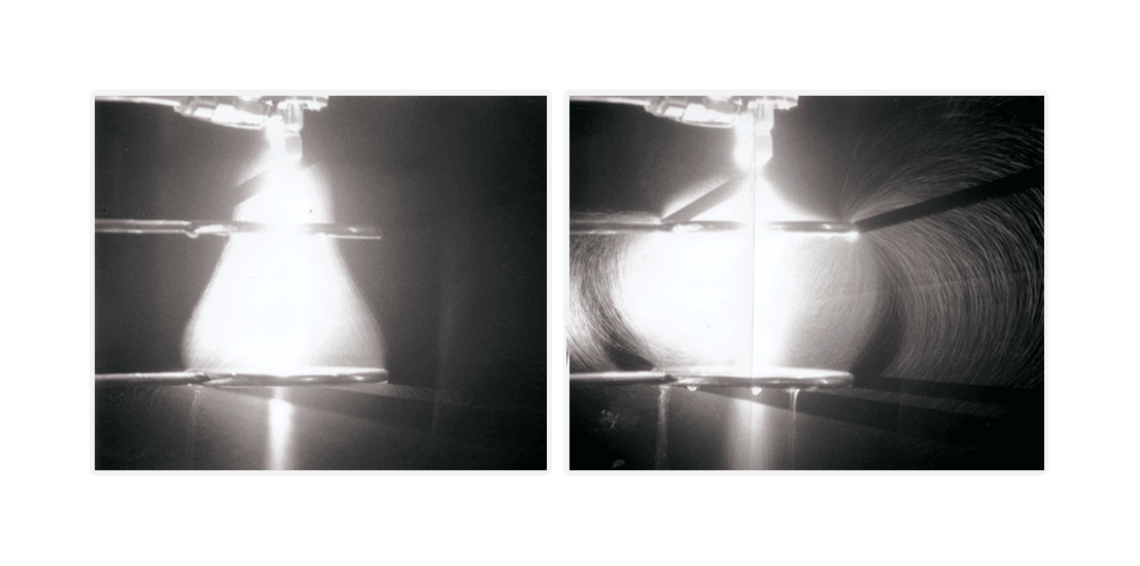

Experimental Arrangement

The rig for the electrostatic atomization experiment consists of a flow circuit (left side) and electric circuit (right side) in the figure. The liquid is forced through the filters and then the atomizer by a pressurized tank. The applied voltage is controlled by a High Voltage Power Supply (HVPS). The charged drops are collected in a grounded sink, which is also used for measuring the spray charge.

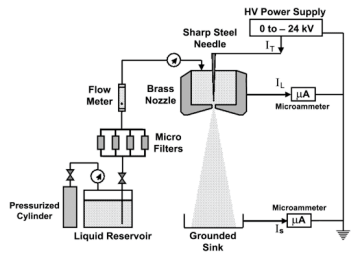

Primary Atomization

Electrical charge has a significant effect on primary atomization for a very small power overhead. For example, Fig. electrostatic-Egemen shows a Diesel oil jet at a bulk velocity of U=50 m/s emerging from an orifice diameter of d=2500 micron and clearly, primary atomization due to aerodynamic forces is minimal (subfigure (a)). Subfigures (b)-(d) show the jet, under the same conditions, but with increasing the magnitude of the applied voltage from 6kV to 17kV, and the enhancement of primary atomization is clearly visible. It should be noted that the additional electrical power requirement is only in the order of mW.

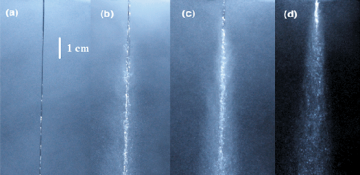

Spray Dispersion & Control

The effect of electric charge goes beyond primary atomization, in that it continues to force drops to recede from their neighbors due to their similar negative charges. The trajectories of the charged droplets can be controlled by applying an external electric field. These droplets are also easily attracted to metal surfaces that are grounded. This latter effect is crucially beneficial to coating applications by enabling targeted deposition, which results in reduced waste and cleanup effort.

Example

The spray dispersion can easily be controlled by applying an external electric field using two rings.