Rechargeable Ion Battery

Vitaliy Yurkiv and Farzad Mashayek

Nowadays, the usage of most appliances and products would not be possible without portable and affordable electrochemical energy storage (i.e. battery). In this regard batteries are ubiquitous, however, still, further advances in capacity, lifetime, and cost of batteries is required to open up new possibilities and markets. In order to meet the necessary requirements, the replacement of battery components (e.g. graphite) is of imperative importance for future battery development. In our work we investigate the alternative electrode materials (e.g. Si, Sn), which are the promising candidate for next-generation electrochemical energy storage.

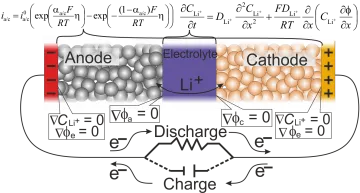

Modeling of the Electrochemical Performance of Lithium Batteries

In the quest for developing high performance and high energy density lithium(Li)-ion batteries, liquid-electrolyte based electrolyte Li-ion batteries are facing a grand challenge: flammability of the batteries. Such concerns are originated from the combustibility of the organic electrolytes. One of the successful solutions towards the improvement of battery safety is the usage of solid electrolytes instead of flammable organic liquid ones.

Thus, the goal of our work is to gain a fundamental understanding of electrochemical and degradation mechanisms of solid-state battery by taking into account electrode/electrolyte microstructure. For the assessment of the electrochemical and degradation phenomena in the continuum modeling approach we use commercially available COMSOL software. The solid-state battery is a reacting-diffusive system, that is, electrochemistry is coupled to transport processes and in the model this system is expressed through a set of coupled differential equations, which are solved numerically. The model describes the electrode, electrolyte, and the interface between those elements employing continuum approach and it provides useful information about the various diffusion and migration fluxes, concentration profiles, and the corresponding overpotential contributions, occurring across the electrode and electrolyte.

Modeling framework for the simulation of Li-ion batteries

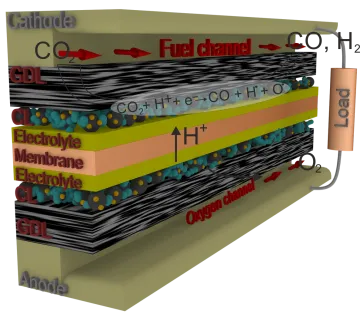

Electrochemical conversion of CO2 in the electrolysis cells

Over the last decades, careless human activity and a vast usage of fossil fuels for energy gain has led to a large release of green-house gases negatively impacting the climate change. Thus, there is an increased need to develop efficient energy conversion technologies that would reduce carbon-footprint. In this regard, the low temperature electrochemical cell (LTEC) is a promising alternative technology for reducing amount of atmospheric pollution. The goal of our modeling research in this area is to significantly increase the fundamental understanding of the low temperature electrochemical cell by developing and applying advanced theoretical methods in a multi-disciplinary approach. We consider the modeling of the following processes – Electrocatalytic mechanisms at the electrodes, in particular at the cathode, operated on CO2 in contact with the catalytic layer and the aqueous electrolyte. – Porous transport of mass and its multi-scale coupling with the catalytic layer electro-(chemistry). – Multi-scale coupling of the predictive electrode-level models for cell-level integration and optimization.

Modeling framework for the simulation of CO2 conversion

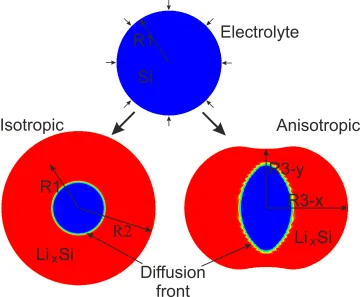

Modeling Elasto-Plastic Deformation in Lithium-ion Batteries

The understanding of elasto-plastic deformation is crucial for performance and durability of Lithium (Li) ion batteries. In our group, we are developing a generic framework to describe kinetics of alternative electrodes (e.g. Silicon) lithiation and its effect on structural changes, stress evolution and mechanical properties. Two models have been developed, where the first approach is a coupled finite element elasto-plastic model using ANSYS finite element package, and the second is a phase-field model based upon MOOSE framework. The models include the description of the lithiation induced phase transformation, morphological evolution and stress generation in Si nanowires.

Isotropic (left) and anisotropic (right) expansion of silicon nanowire during the lithiation

Silicon lithiation

We can analyze the fracture of electrodes due to the strain effect of lithiation.

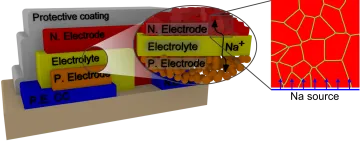

Phase-field modelling of Na-ion battery

We have developed a phase-field model of of Na intercalation into thin film electrodes. The model takes into account diffusion/intercalation kinetics within the grain boundary and the grains, and an elastic electrode deformation together with the grain boundary evolution.

Density Functional Theory (DFT)

DFT simulations provide a means to calculate the minimum energy of a system. This concept is used in our research to determine the most probable path of ion diffusion in the anode. This is typically accomplished by calculating the energy required for ion moving through different possible paths.

The preferred path is the one that requires the least amount of energy. DFT simulations are conducted using the open-source software QUANTUM-Espresso.

Calculation software packages

In our work we mainly use three software packages – ANSYS, MOOSE framework and COMSOL multiphysics.

The ANSYS Mechanical software is a comprehensive finite element analysis tool for structural analysis, including linear, nonlinear, dynamic, hydrodynamic and explicit studies. It provides a complete set of elements behavior, material models and equation solvers for a wide range of mechanical design problems. In our work, the ANSYS coupled diffusion-expansion model for the lithiation of the battery electrodes and their elasto-plastic deformation is used.

MOOSE (Multiphysics Object-Oriented Simulation Environment) is a finite-element, multiphysics framework, which provides a high-level interface to some of the most sophisticated nonlinear solver technology. The MOOSE framework was developed to simplify the creation of fully coupled, nonlinear, multiphysics applications, where each application is made up of physics “modules” that describe the PDEs to be solved, material properties, boundary and initial conditions, postprocessed quantities, etc. In our work, we use MOOSE for the phase-field based numerical simulations.

COMSOL Multiphysics® is a general-purpose software platform, based on advanced numerical methods, for modeling and simulating physics-based problems. In our work, the COMSOL is used for electrochemical calculation in the battery and flow cells areas.

In addition, we use different codes such as Cantera, Chemkin.